Article

Introducing the new Bruker D6 PHASER XRD Benchtop X-Ray Diffraction Platform for Materials Analysis and Advanced Research

Pollution caused by plastic waste is a major global concern. Millions of tons of plastic waste materials end up in different oceans. These wastes are degraded by various mechanical and chemical forces, such as ocean waves and photo-oxidation by sunlight. These forces transform plastics into small fragments. Scientists and researchers are turning to Pyrolysis GC-MS for microplastics detection and identification as the backbone of their research.

[Learn more: 5 reasons labs are using Pyrolysis GC/MS to power their microplastics analysis and research.]

Plastic fragments that are less than 5 mm in size are called microplastics. Due the growing threat of microplastics to humans and our planet, health and environmental testing laboratories are seeking an accurate and rapid analytical technique for characterization and analysis of microplastics. Being able to measure the amount of microplastics in seawater is key to recognizing the effects on aquatic life.

In this application article, the primary solution is the Multi-Functional Pyrolysis Solution. A multi-functional, micro-furnace pyrolyzer called the Frontier EGA/PY-3030D multi-shot pyrolyzer is a preferred instrument for researchers and chemists in the field of microplastics research.

Micro-furnace Pyrolysis GC-MS has been proven to be an accurate, rapid, and simple analytical instrumentation for the identification of various polymers and additives in microplastics. This technique simplifies sample preparation and provides detailed information about the chemical composition of microplastics.

Micro-furnace Pyrolysis GC-MS is composed of a vertical micro-furnace multi-mode pyrolyzer that directly interfaces to a GC/MS system. The micro-furnace performs continuous pyrolysis where all the pyrolyzates are directly and continuously deposited on the GC column as they are generated. Because of this design, there is no transfer line and no active-site.

[Learn More: Understanding the Different Types of Pyrolyzers]

In addition to the EGA/PY-3030D instrument, the team used a powerful polymer search engine called F-Search. F-Search is an excellent tool for the pyrolysis scientist. Mass spectral search software identifies polymers and additives based on EGA thermograms and pyrograms obtained using a Pyrolysis-GC/MS system. The system consists of search software and four libraries. F-Search improves the reliability of analysis results by comparing data from different analysis methods. In addition, its patented search algorithm allows for reliable results even with data obtained by different analysis conditions.

Frontier Lab has been involved in the microplastics research industry since the early days. And through this, they pioneered the powerful F-Search MPs 2.1 – a version of F-Search specifically designed for the microplastics researcher. F-Search MPs allows users to easily identify and quantify unknown microplastics in the environment.

[Learn More: F-Search MPs 2.1 Software for Microplastics Analysis]

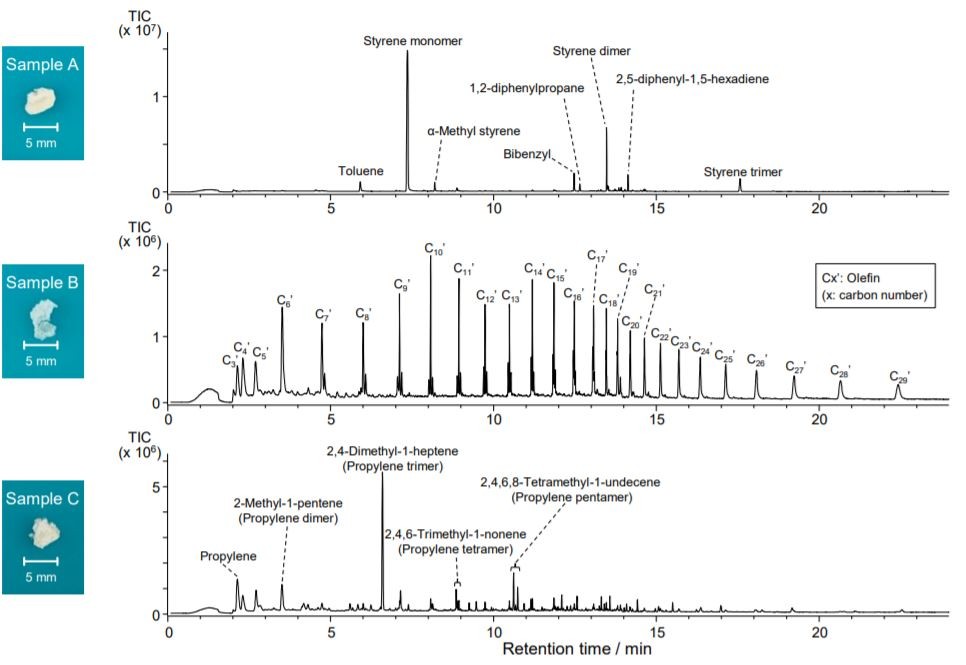

Three different white microplastics samples collected from the surface water at Osaka Bay. They were cut into ca. 1 mm squares and placed in an Eco-Cup LF (volume 80 µL). The Eco-Cup was dropped into the pyrolyzer furnace pre-heated to 600 ºC.

The degradation products (pyrolyzates) were separated on a UA+ -5 column and detected by a quadrupole mass spectrometer. Pyrograms of the three microplastics samples obtained by Py-GC/MS are shown in Fig. 1. The library search by F-Search “All-In-One” revealed that Samples A, B, and C are polystyrene, polyethylene, and polypropylene, respectively.

Pyrolysis temp.: 600 ºC, GC inj. temp.: 300 ºC, GC oven temp.: 40 (2 min hold) – 320 ºC (20 ºC/min, 16 min hold), Split ratio: 1/16 Separation column: UA+ – 5 (5 % diphenyl 95 % dimethylpolysiloxane), L=30 m, id=0.25 mm, df=0.5 µm, Column flow rate: 1 mL/min (He) Scan range: m/z 29 – 350, Scan rate: 4 scan/s, Sample amount: Sample A 35 μg, Sample B 53 μg, Sample C 34 μg

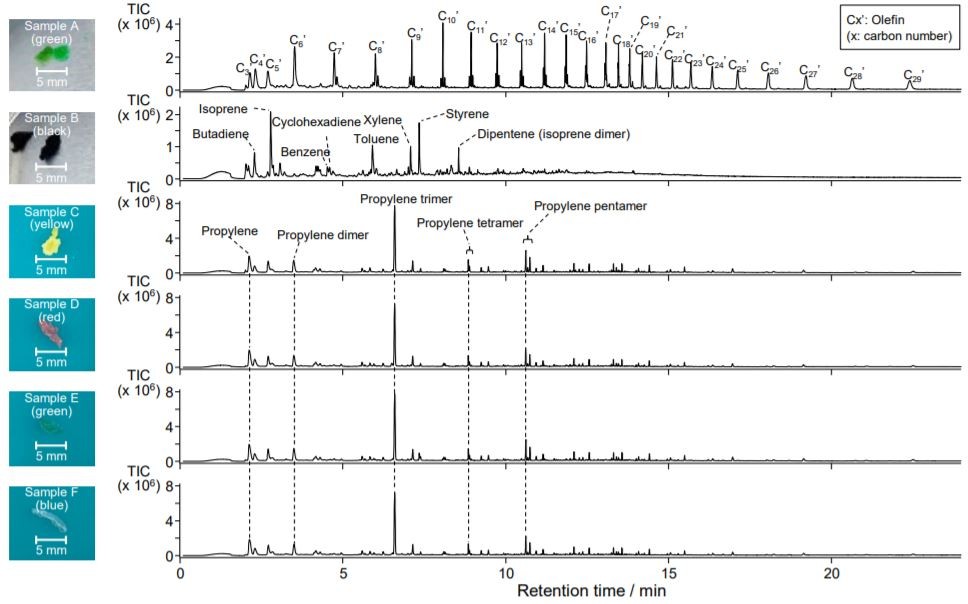

Six different colored microplastics samples were collected from the surface water at Osaka Bay:

All six samples were cut into a ca. 1 mm square with a cutting knife. Each piece was placed in an Eco-Cup LF (volume 80 µL) and introduced into the pyrolyzer furnace pre-heated to 600 ºC for flash pyrolysis. The pyrograms of the six different microplastics samples obtained by Py-GC/MS are shown in Fig. 2.

Through the library search with F-Search “All-In-One”, Sample A was identified as polyethylene, and Samples C to F showed almost the same pyrogram and were identified as polypropylene. From FT-IR measurements, Sample B was identified as ethylene-propylene rubber based on the library search. However, Sample B shows peaks ascribed to isoprene, styrene, and butadiene in its pyrogram (Fig. 2), suggesting that Sample B will be a rubber composed of natural rubber (or isoprene rubber) and styrene-butadiene rubber.

Pyrolysis temp.: 600 ºC, GC inj. temp.: 300 ºC, GC oven temp.: 40 (2 min hold) – 320 ºC (20 ºC/min, 16 min hold), Split ratio: 1/16 Separation column: UA+ -5 (5 % diphenyl 95 % dimethylpolysiloxane), L=30 m, id=0.25 mm, df=0.5 µm, Column flow rate: 1 mL/min (He) Scan range: m/z 29 – 350, Scan rate: 4 scan/s Sample amount: Sample A 102 μg, Sample B 62 μg, Sample C 36 μg, Sample D 37 μg, Sample E 39 μg, Sample F 34 μg

Plastic pollution is one of the most pervasive issues affecting our oceans and water supplies across the globe. In additional to creating issues in water supplied, microplastics have been found to be harmful to marine plant and wildlife. Recently, studies have indicated their presence in drinking water (even bottled water) and in human samples too. These plastics can accumulate organic pollutants that adsorb to them are therefore biomagnified up the food-chain. Several nations have recently banned single-use plastics and have committed to reduce the widespread use of plastics in general.

To support this research, the Frontier EGA/PY-3030D multi-shot pyrolyzer is an effective tool for qualifying and identifying the origin of these microplastics.

References:

Put our expertise, strategic partnerships, and technical support capabilities to work for you.

8301 New Trails Drive, Suite 100, The Woodlands, Texas 77381

© 2024 Quantum Analytics | A Black Forest Ventures Company | All Rights Reserved | Privacy Policy

Complete this form below and we’ll be in touch shortly!

Complete this form below to sign up and we will reach out to you with instructions

Complete this form below to give us some context about you and your needs.

Our sales team will be in touch shortly