Today’s analytical instrumentation buyer has a range of solutions available when it comes to solving their analytical challenges. Narrowing down the best analytical solution includes investigating and researching these different options and techniques. And one of the most important decisions: which brand of instrument to choose.

The analytical instrumentation market is dominated by a handful of companies, including Agilent Technologies, Bruker Corporation, Thermo Fisher Scientific, and others. The major vendors in the market have deep product portfolios that cater to different requirements of the chemists and researchers.

There are also a growing number of smaller manufacturers that have carved out a space in the analytical instrumentation market. And instead of trying to take on the big companies à la David vs. Goliath, these smaller manufacturers are operating in niche segments – offering complimentary instruments and accessories that can help lab managers increase testing throughput with increased confidence in results. In essence, these systems are extending the capabilities of standard platforms – resulting in in what we call multi-vendor analytical instrumentation solutions or multi-vendor solutions for short.

In the analytical instrumentation industry, a multi-vendor solution is an integrated system comprised of instrumentation from more than one instrumentation manufacturer or vendor. Sometimes they are referred to as cross-platform integrated solutions. But semantics aside, anytime two or more instrument vendors are leveraged in a tightly integrated solution, this can result in a powerhouse system that can solve a unique analytical challenge.

Some examples of multi vendor solutions that Quantum Analytics offers:

The first multi vendor solution we’ll explore is pyrolysis-gas chromatography-mass spectrometry. It is often abbreviated as pyrolysis GC-MS, PY-GC/MS, or Pyr-GC/MS. It is a powerful and simple technique comprised of a pyrolyzer coupled with a gas chromatography mass spectrometer system. Using this technique, sufficient heat is used to break down the organic bonds of a complex species into smaller and stable molecules referred to as pyrolyzates. The pyrolyzates form and their relative intensities provide insight into the nature of the original material.

This technique has a wide variety of applications for identifying organic composition of unknown samples by providing detailed information about the compounds present in a sample: molecular formula, structure, and eluting time.

In addition, Pyrolysis GC-MS is used for identification of complex polymers, copolymers, volatiles, and additives. This technique which can be used both qualitatively and quantitatively, allows multiple and customized analysis on the same sample.

Quantum Analytics is the exclusive distributor of Frontier pyrolysis solutions integrated with the Agilent platform. The Frontier multi-shot pyrolyzer delivers high-performance and ease of use features. Some analytical techniques using Frontier Pyrolysis are listed below as examples. These techniques help you quickly solve the most difficult analytical challenges in an efficient and effective way.

This multi-vendor solution is gaining greater popularity as of late due to the growing need for quantifying microplastics in environmental samples.

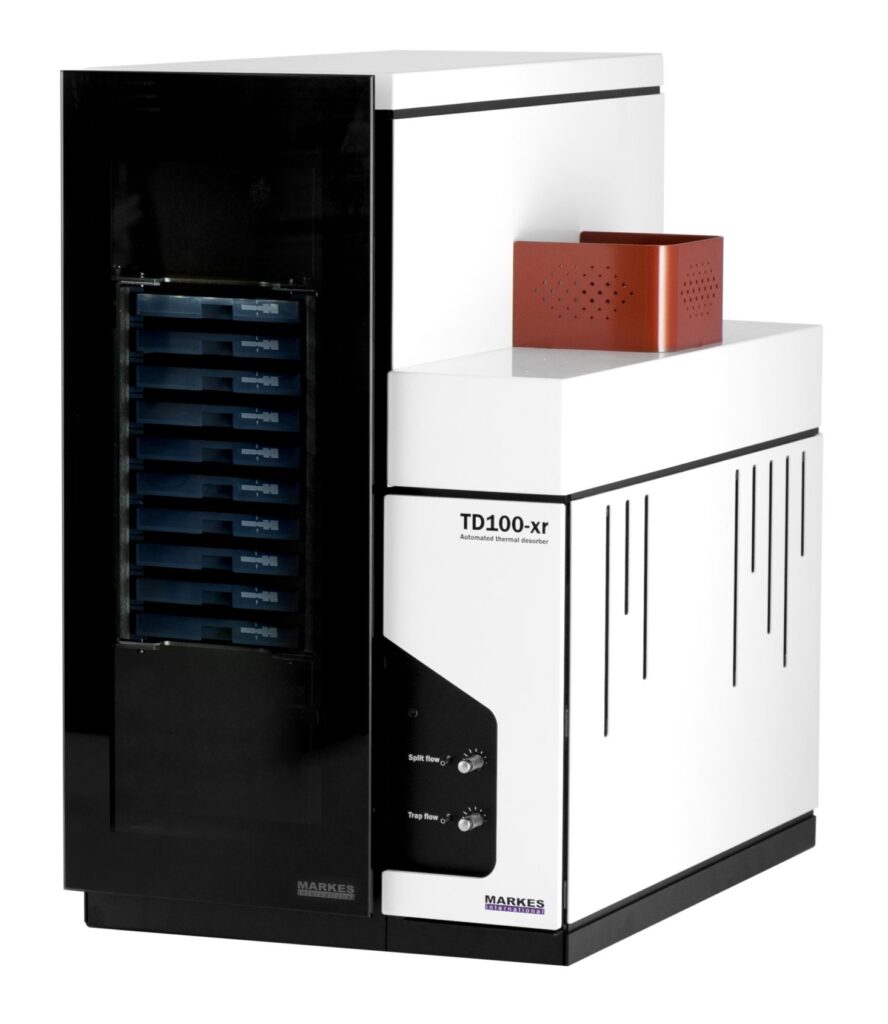

The second multi-vendor solution we’ll outline here is thermal desorption-gas chromatography-mass spectrometry. This is also referred to as TD-GC/MS. Analytical thermal desorption is a sample preparation and introduction technique for gas chromatography that overcomes the drawbacks of conventional sample preparation techniques, such as solvent extraction, solid-phase micro-extraction, purge-and-trap and static headspace.

Advantages of thermal desorption include:

Thermal desorption is an incredibly dynamic technique. Here are just a few examples of applications that are ideally suited for thermal desorption-GC/MS:

Quantum Analytics is an authorized distributor for the Markes International line of thermal desorption systems.

Flexible financing, technical services, and refurbished instruments.

Everything you need to advance your lab’s success – all in one place.

8301 New Trails Drive, Suite 100, The Woodlands, Texas 77381

Complete this form below to sign up and we will reach out to you with instructions