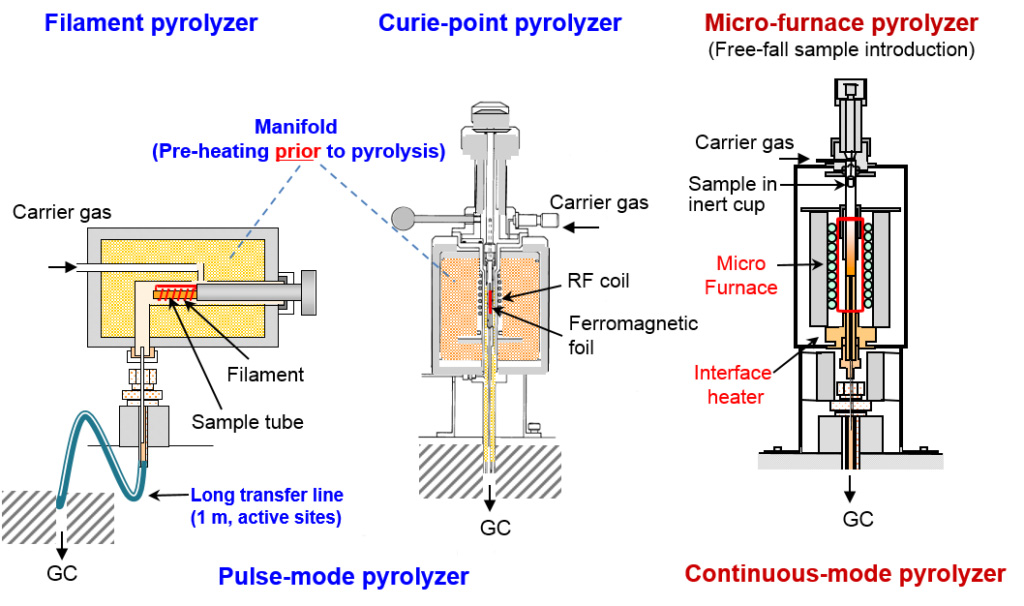

In fact, there are three different types of pyrolyzers that are commercially available:

All types of pyrolyzers can perform flash pyrolysis. However, it’s important to understand how each pyrolyzer type differs.

The pyrolysis temperature cannot be tuned continuously by a Curie-point pyrolyzer. Because of this, Curie-point pyrolyzers are unsuitable for evolved gas analysis (EGA). Filament pyrolyzers can’t analyze volatile or semi-volatile compounds effectively. The system requires sample pre-heating to prevent condensation of high-boiling pyrolyzates.

A temperature-programmable micro-furnace pyrolyzer performs both flash pyrolysis and EGA. Since the micro-furnace connects directly to the GC without cold spots, a cryo-trap is usually unnecessary.

To better understand the different types of pyrolyzers, the sections below explain each pyrolyzer’s specification. Here is a great video to explain the key differences.

The first type of pyrolyzer we’ll cover is the Filament Type Pyrolyzer. In short, filament type pyrolyzers heat a sample tube with a filament.

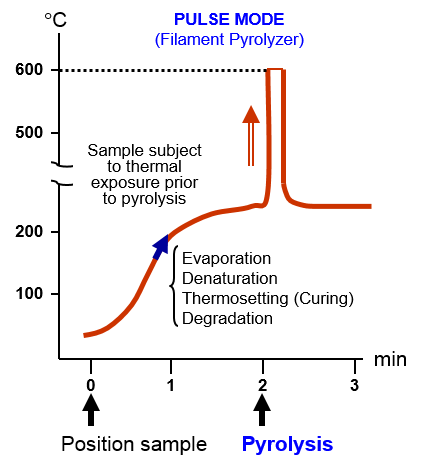

Filament pyrolyzers suffer from non-uniform heating. This reduces temperature accuracy and affects reproducibility. Sample temperature varies based on its position near the platinum coils and how well it contacts the filament.

The system estimates filament temperature from electrical properties, but it doesn’t measure changing sample temperature directly. You must pre-heat the sample prior to the analysis in the heating manifold to avoid the condensation of pyrolyzates with a high boiling point.

And herein lies the problem: this preheating step causes denaturation, degradation, and thermosetting of samples and evaporation of volatile and semi-volatile compounds in samples.

Some filament pyrolysis systems use a 2-step pyrolysis process. In the first step, the system collects some pyrolyzates off-line on a focusing trap. A switching valve directs pyrolyzates into the GC/MS.

This two-step process transfers pyrolyzates indirectly to the GC column. Polar and heavy compounds often stick in the trap and don’t get analyzed, similar to what happens in a cold spot.

In short, filament pyrolyzers can’t analyze volatile or semi-volatile compounds effectively.

Fig. 2 Thermal Profile of a Filament Pyrolyzer

Next, let’s look at the Curie-point pyrolyzer. Curie-point pyrolysis systems can have a high heating temperature accuracy. However, the heating temperature depends on the alloy composition of the sample foil. As a result, Curie-point pyrolyzers can’t support continuous temperature increases required for EGA. The system requires pre-heating of the heater manifold, similar to the filament pyrolyzer.

Herein lies the problem: Depending on how the sample is wrapped with the alloy foil, results can vary which leads to poor reproducibility.

Even with advanced GC and MS tools, sample preparation remains a major challenge. Preparing a sample that contains non-volatile, insoluble materials and chemicals can be tricky. Sample preparation can require a lot of time and expertise particularly when dealing with small sample amounts.

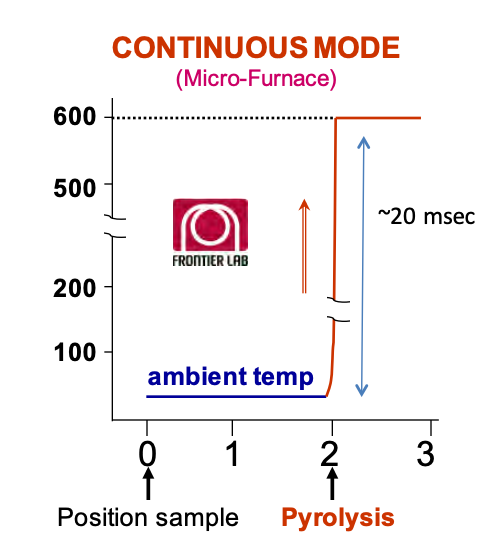

Fig. 3 Thermal Profile of a Micro-Furnace Pyrolyzer

Finally, we have the Micro-furnace pyrolyzer. The micro-furnace design allows a full range EGA to obtain a thermal profile of an unknown sample for light compounds, volatiles, and additives as well as oligomers, heavy, and polymeric compounds. You can perform EGA experiments from 40 °C to 1050 °C. The system correlates results with well-established TGA techniques throughout the entire temperature range of the experiment.

The capability of Micro-furnace pyrolyzers is critical for analyzing unknown samples.

This technology directly deposits all pyrolyzates on-column in a single step process for a continuous-mode analysis. The chemist places the sample in an inert, deactivated cup held at the ambient temperature in helium. The system prevents heat exposure prior to the analysis. The micro-furnace is preheated to the desired temperature. The temperature is precisely measured with a thermal couple sensor near the sample. The sample cup then drops into the quartz pyrolysis tube, where the sample is quickly and reproducibly pyrolyzed. The carrier gas sweeps pyrolyzates continuously onto the GC column for separation and detection by MS or any other detector.

The continuous-mode process of the micro-furnace allows low and high molecular-weight, as well as polar compounds to be detected and analyzed. Eliminating the transfer line enhances the ability to detect heavy and polar pyrolyzates.

Micro-furnace technology guarantees reproducibility and accuracy of the temperature with ±0.1 °C. Every facet of the system is designed to ensure reliability and data quality. All wetted surfaces are quartz or temperature stable deactivated. There is no transfer line with cold spots and no cross contamination.

The Frontier EGA/PY-3030D Multi-Shot Pyrolyzer is a sophisticated and powerful instrument based on a micro-furnace design. It features high performance and ease of use, from the heating furnace to the control software. The Frontier EGA/PY-3030D is a versatile multi-shot pyrolyzer that offers temperature programmability from ambient (+10 ᵒC) to 1050 ᵒC with precise temperature control (+/- 0.1 ᵒC) of the ceramic micro furnace. Users can analyze materials using a variety of techniques for greater flexibility.

It is important to note that based on actual bond energy strengths in polymers and materials, all organic materials will pyrolyze prior to a temperature of approximately 700 °C. The only reason to set an initial pyrolysis temperature in excess of 700 °C is because the actual sample temperature in the pyrolyzer is not accurate.

Its important to be wary of any literature indicating pyrolysis at 1,200 or 1,300 °C is either unnecessary, over pyrolysis, or indicates poor actual sample temperature control in the particular pyrolysis device.

Learn more about the Frontier micro-furnace pyrolyzer and request pricing information.

References:

Complete this form below to sign up and we will reach out to you with instructions