Manufacturers in the automotive industry widely use Advanced Composite Materials, also known as Advanced Polymer Matrix Composites. Experts classify these composites by their matrix phase. One key classification, Ceramic Matrix Composites, serves several roles in automotive manufacturing, including brake disk production.

In this brief, we show how researchers use the Pyrolysis-GC/MS technique to analyze ceramic composite materials for automotive applications.

In this brief, we’ll outline the analysis of a ceramic composite material in which various additives have been added to aluminum oxide during the manufacturing process.

To demonstrate this technique, we analyzed ceramic composites using the Frontier EGA/PY-3030D Multi-Shot Pyrolyzer, shown in Figure 1. This experiment involved aluminum oxide infused with various additives during manufacturing.

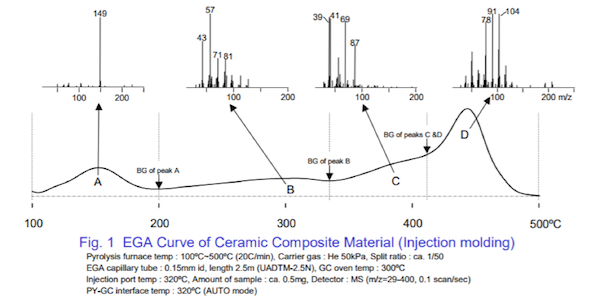

To begin, we drop the sample into a furnace set to a low initial temperature. Then, we program the furnace to increase to 500 °C at 20 °C/min. As the temperature rises, compounds evolve from the sample. As a result, the system generates a plot of detector response versus furnace temperature, providing a thermal profile of the composite material.

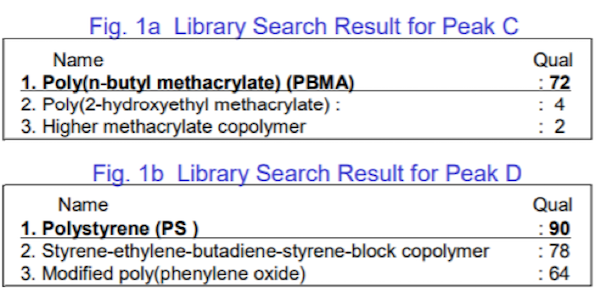

Next, we identified the sample’s chemical components using the F-Search engine from Frontier Laboratories. This tool compares EGA spectra against four specialized libraries:

Each library provides both chromatographic and mass spectral data. Fig. 1. shows the EGA curve and average spectra of peaks A, B, C, and D observed for the composite material. Background (BG) noise has been subtracted from the average spectra.

The libraries include both chromatographic and mass spectral data. The F-Search Engine Figs. 1a and 1b show the results of library search using the F-Search EGA-MS for the spectra obtained. We identified Peaks C and D as PBMA and PS, respectively, with high confidence based on library matches. Because of their lower elution temperatures, Peaks A and B were determined to be low-boiling compounds. A standard MS library search indicated that Peak A is a phthalate ester, and Peak B consists of saturated hydrocarbons.

Therefore, upon searching normal MS library, Peak A was judged to be a phthalate ester, and Peak B saturated hydrocarbons. As shown here, combining results from the MS and EGA-MS libraries proves especially effective for identifying unknown components in advanced composite materials.

In summary, the Frontier Multi-Shot Pyrolyzer offers a powerful way to analyze advanced ceramic composites. It delivers a clear picture of a sample’s composition by identifying thermal zones and the compounds in each.

After obtaining the EGA thermogram, you can program the ideal temperature range for further analysis. The instrument allows multiple analyses on a single sample, eliminating the need for solvents. Solid samples can be introduced directly into the system.

F-Search displays the total ion chromatogram (TIC) and mass spectrum on a single screen, allowing users to subtract background signals and isolate high-quality spectra.

Its extensive libraries include:

References:

Flexible financing, technical services, and refurbished instruments.

Everything you need to advance your lab’s success – all in one place.

8301 New Trails Drive, Suite 100, The Woodlands, Texas 77381

Complete this form below to sign up and we will reach out to you with instructions