Thermoset resins are materials that strengthen when heated and permanently retain their shape. Once formed, you cannot remold or reheat them. For this reason, manufacturers across industries use thermosets for their rigidity, durability, and resistance to high temperatures. Which also means there is a growing need for analyzing thermoset resins across the supply chain.

Thermosets are a class of polymers that undergo a permanent chemical reaction – called curing – to form a solid structure. Also referred to as thermosetting plastics or resins, they differ from thermoplastics in that they cannot be melted and reshaped once cured.

When fully cured, thermoset resins are rigid, typically insoluble solid materials of high mechanical strength and hot temperature stability. In contrast to thermoplastics, thermosets cannot be melted and remolded to other shapes after curing.

Because of their unique properties, thermosetting resins improve the chemical resistance, structural integrity, and thermal stability of many products. As a result, they are commonly used in automotive, electrical, lighting, and energy sectors for parts that demand durability, strength, and moldability.

Thermoset plastic composites are cost-effective and versatile, meeting a wide range of production requirements. Additionally, they support high-volume manufacturing while maintaining consistency from batch to batch. In situations where complex or geometric shapes can’t be produced using metal fabrication or thermoplastics, you can manufacture them in a mold using thermosets. These materials maintain their form and integrity across all environments and temperatures.

Thermosets come in a variety of forms, depending on the application. Examples include:

To ensure quality throughout the supply chain, accurate analysis of thermoset resin composition is critical.

In this article, we explore analyzing thermoset resins. Specifically, we’ll look at understanding their chemical structure using the Frontier EGA/PY-3030D multi-functional pyrolyzer integrated with a GC/MS system. This method requires no solvent or sample preparation.

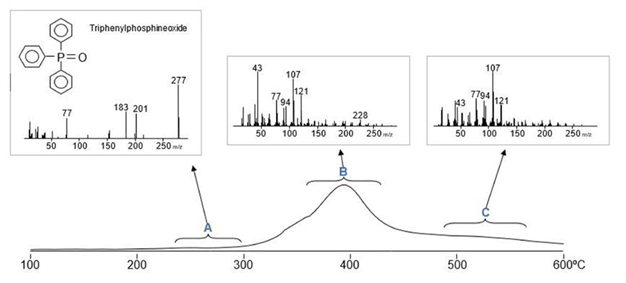

To begin, we performed Evolved Gas Analysis (EGA) between 100 and 600 °C at a rate of 20 °C/min. EGA is one of the operating modes of the micro-furnace pyrolyzer. In this setup, no analytical column is used. Instead, a short, deactivated stainless-steel tube (2.5 m, 0.15 mm i.d.) connects the GC injection port to the detector.

The sample is dropped into a low-temperature furnace (100 °C), then heated to 600 °C. As the temperature rises, compounds evolve from the sample. The resulting detector response vs. temperature plot reveals the thermal behavior of the resin.

Figure 1 shows the EGA thermogram and the averaged spectra for regions A, B, and C. In region A, we found Triphenylphosphine oxide, a common reaction catalyst. In region B, cresol and phenol resins appeared. Region C showed further cresol resin content.

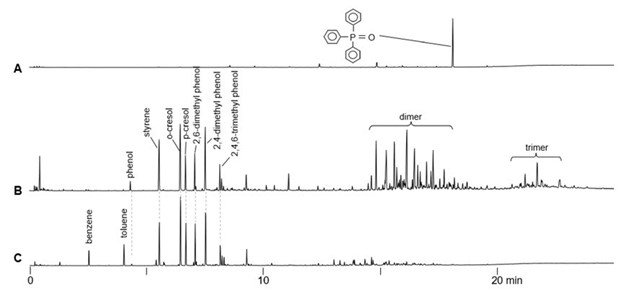

Next, we used the heart-cutting mode to isolate each thermal region. Heart-cutting involves slicing temperature zones (A, B, and C) identified in the EGA thermogram for individual chemical analysis. Figure 2 shows the resulting chromatograms.

Triphenylphosphine oxide appeared again in region A. Regions B and C revealed phenols and styrene monomer—both products of thermal decomposition.

The Frontier EGA/PY-3030D pyrolyzer enables multiple analyses on a single sample—including volatiles, polar compounds, heavy organics, and polymers. It connects directly to the GC injection port without a transfer line, focus trap, or switching valves. As a result, you avoid degradation, cross-contamination, and active site interactions. Pyrolyzates flow directly and continuously to the analytical column for accurate results.

Quantum Analytics is proud to serve as an official distributor and service provider for Frontier Labs in the United States. To learn more about this pyrolysis solution, reach out to our team.

Complete this form below to sign up and we will reach out to you with instructions