For years, X-ray analysis has been used by manufacturers to study and characterize materials for research and quality assurance. Two popular techniques that incorporate X-ray analysis for sample analysis are X-ray Fluorescence (XRF) and X-ray Diffraction (XRD). Both XRD and XRF techniques measure a sample’s response to the X-rays, but provide different types of measurements. A growing number of companies are applying both XRD and XRF for their material characterization applications. And for good reason!

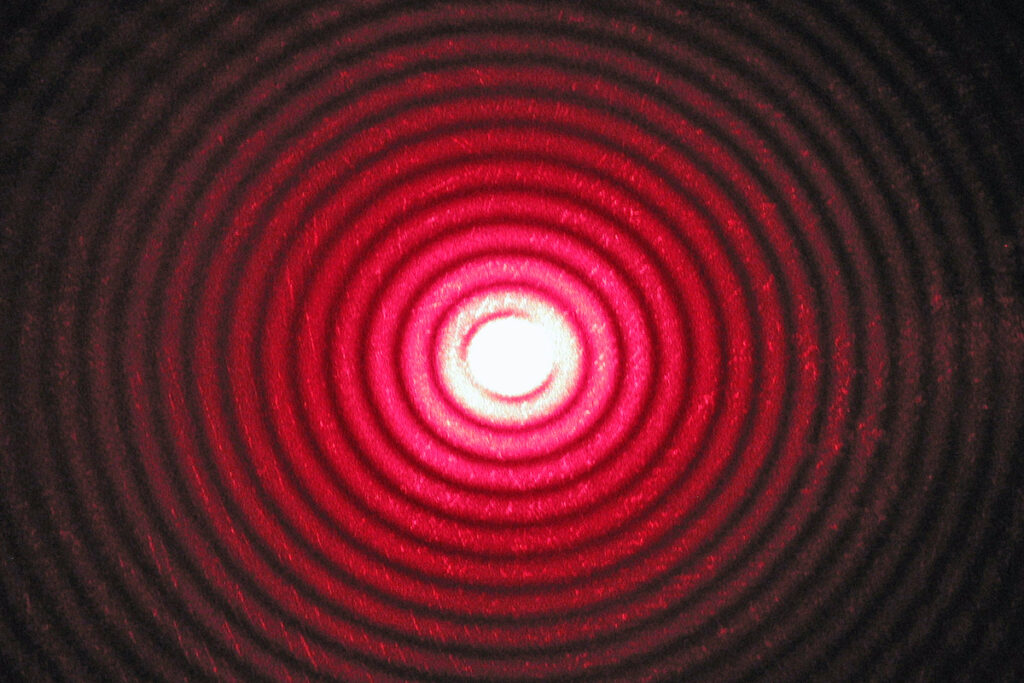

XRF provides the elemental data for chemical composition without differentiating between the different chemical compounds that are present in the sample. XRD identifies and measures the presence and amounts of minerals and their species in the sample. XRD is also used to analyze phase composition and structure.

Although XRF and XRD provide different information, they complement one another and give a total picture of sample composition. A major advantage of both XRF and XRD compared to other elemental analysis techniques is that they are non-destructive. This means that the sample can be recovered for other confirmatory tests. First, in order to better understand the differences between XRF and XRD it is important to have clarity on the two techniques.

Flexible financing, technical services, and refurbished instruments.

Everything you need to advance your lab’s success – all in one place.

8301 New Trails Drive, Suite 100, The Woodlands, Texas 77381

Complete this form below to sign up and we will reach out to you with instructions